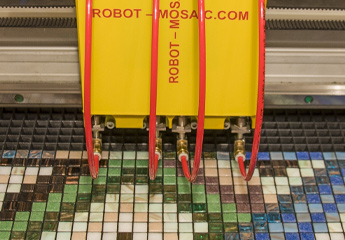

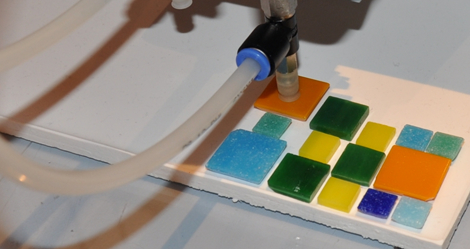

Robot-mosaic is a ready-made technological solution for laying out a mosaic of a photo; a robot-controlled machine performs the process.

Wide range of mosaic chips dimension types can be used for robot-controlled process of mosaic laying. The most popular sizes of mosaic are 10 x 10 mm, 15 х 15 mm, 20 х 20 mm.

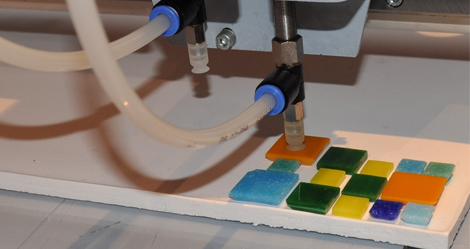

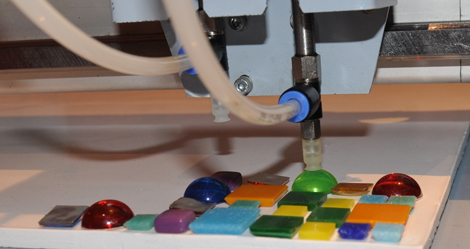

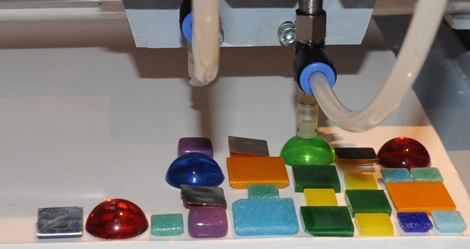

Different forms (square, rectangular, round, oval) are used for mosaic chips, so the surface can be convex. The height of the mosaic chip can reach 15 mm. Using a different mosaic height, you can create an embossed surface effect.

At the request of the customer, it is possible to retrofit a machine with the removable suction cup mechanism for a mosaic of 5 x 5 mm and smaller sizes.

Machine can be checked and production tested. Machine is a low maintenance mechanism, reliable and easy-to-operate.