Modern society is moving towards customization and uniqueness. Consumers are less willing to be like everyone, they tend to show their individuality and uniqueness more and more. Owners of houses, hotels, restaurants want to make their place the most beautiful one, unique and different from others.

We were able to automate one of the most complex processes in decoration, modeling and assembling of the mosaic panel.

Using the latest technology in robot industry, we offer a low-cost equipment for small and medium-sized businesses. The machinery is able to make an individual approach to each client simple.

Our robot and related software allow you to lay a mosaic of the photo or picture of almost any size.

Video – robot-controlled process of mosaic assembly

The modern mosaic market offers products in the form of a finished assembled drawing, and, as a rule, the drawing is not intricate nor complex.

Custom-built mosaic panels are assembled manually and are expensive because of the large amount of manual work. Robot-controlled mosaic (based on clients’ photo) assembly is a new service in finishing and remodeling. The price of mosaic panel, assembled by robot-controlled machine, is not higher than the price of a conventional mosaic. Therefore, why would the costumer buy a conventional mosaic, when for the same price he can order a mosaic painting?

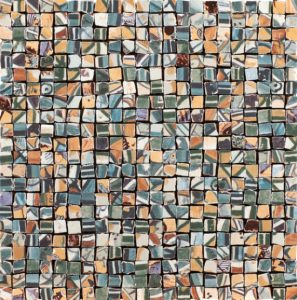

Let’s compare the samples of mosaics selling in the stores,

and mosaic “Alexander mosaic”,

in fact the production cost per square metre of these examples are the same (as both made of the same material). The only one difference in the cost – is the cost of assembling (the combination and location) different tiles of mosaic.

The uniqueness of the technology

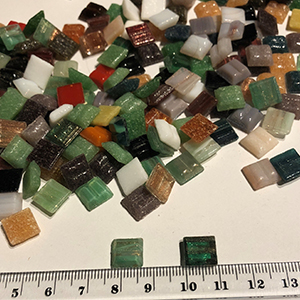

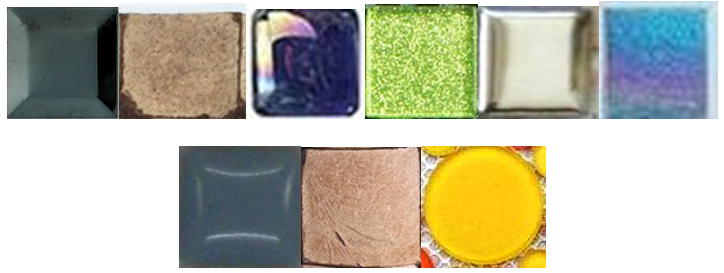

The most popular mosaic tiles are:

Trapezoid

Sintered glass

Glitter glass

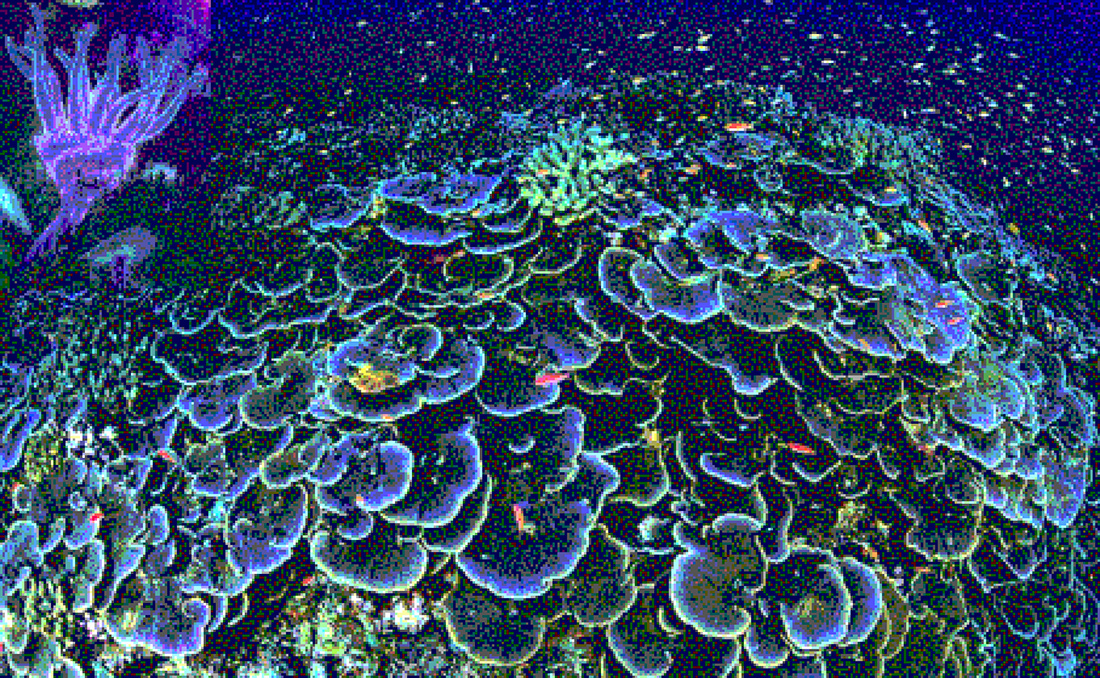

The uniqueness of the technology is that the robot allows you to collect a mosaic of each type of chip separately, and combine them together in a single picture. For example, the mosaic “Corals in the moonlight” – the edges of the corals glow a little. Using all three types of mosaic chips, you can make a mosaic picture in which the corals will glisten and glow a little. Because the glittery chip is slightly higher, the mosaic on the wall will have a small relief (texture).

Using our solution, you can establish your own mosaic-laying center. Clients from different cities would be able to send you photos of the desired mosaic, you would than lay the mosaic panels and send it back to the clients. After that, the client would need only to glue the mosaic to the wall with help of a contractor or on his or her own.

Machine allows you to lay parts of mosaic plates by sheets (sets) of up to 50 cm wide and 3 cm long, so to lay mosaic picture of 3 х 3 meters, you shall glue only 12 parts. This dimensional feature allows to significantly reduce the requirements for the qualification of the worker gluing the mosaic – the less the number of spares needed to be assembled, the easier and more accurate will be the seam joining. For comparison, the size of standard sheet (set) for mounting of the mosaic panel on the surface is about 30 x 30 cm, to lay a panel of 3 x 3 meters, you would need 100 such parts (8 times more!).

Our solution allows you to significantly reduce the time required to transform the idea into the finished product, the automation of the process helps to reduce the cost of laying.

Your clients shall only find suitable pattern or photo, and you will make the mosaic panel of it.

Robot-controlled assembly will allow you to fill any order, from mittens, snowflakes, etc:

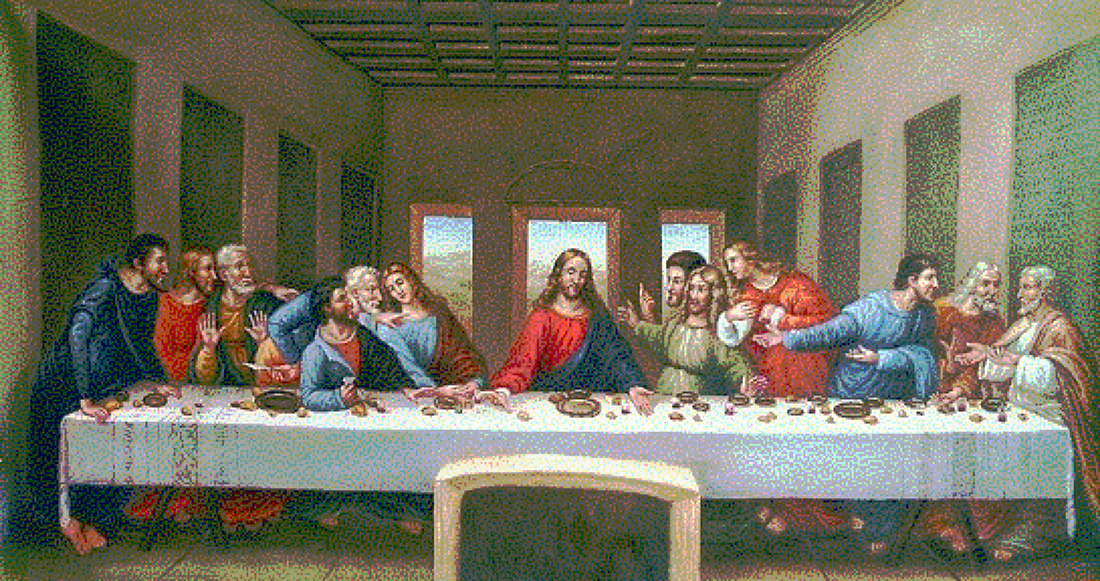

to the famous paintings reproductions (The Last Supper – Da Vinci): mosaic panel, 6,0 х 3,2 meter (10 х 10 mm chip size, the distance between chips is 1 mm.)

“Smeshariki” cartoon characters, mosaic panel of 2,9 х 1,6 meter, 15 х 15 mm chip size:

Your clients shall only find suitable pattern or photo, and you will make the mosaic panel of it.

The machine allows you to ‘paint’ patterns and paintings on mosaic panel. The machine operates as printer, mosaic chips are used instead of paint (mosaic printer).

Our equipment solution will benefit restorers and artists working with mosaics in churches and temples. As a rule, the size of the mosaic in churches and temples is quite large and mosaic drawing by hand takes a lot of time.

Designers, working on the remodeling, will find our product useful. They will be able to offer their clients exclusive custom design.

Designers and artists working on large mosaic laying (from 10 meters) will find our product irreplaceable.

For example, mosaic on the facade of “Krasniy Oktyabr” (“Red October”) cinema building:

Manual laying of mosaic panel of this size would take up to a year of a hard work, whereas our equipment can reduce the execution period to several months.

Mosaic of hotels, shops, boutiques, and companies logo in the lobby will look prestigious and stylish, emphasizing the respectability of the owner.

Quality of the original image

The software can perform mosaic layout of almost any size, taking a photo with a small resolution as a basis.

For example, we downloaded this photo from the Internet (searching for “Sailing vessel” in “Google pictures”).

The picture size is 81 kb, 346 x 81 (wide x height) pixel.

The machine can lay a mosaic of this picture of 10-meter high and 10 meter wide. Therefore, our robot will help you to create a mosaic of almost any picture such as photo form social network, screenshot, image from MSQRD or Prisma.

High speed operation

On average robot (4 suction cups) lays mosaic at a rate of 1 chip per 1.1 seconds.

Using 20 colors, we laid mosaic of “Scarlet sails” of 2.5 meters high and 3.2 meters wide. The result is the following:

Mosaic chips size is 10 х 10 mm. The distance between mosaic chips is 1 mm. Number of mosaic chips is 67 192 pcs.(number of mosaic chips in one row is 296 pcs., number of mosaic chips in one column is 227 pcs.).

The rate of mosaic panel laying – around 20.5 hours (67 192 pcs. х1,1 sec. / 60 sec.= 1 232 min / 60 min. = around 20,5 hours of machine operation).

Mosaic paining of the same size, laid with chip size of 20 Х 20 mm will require 18 445 chip pcs, (number of mosaic chips in one row is 155 pcs., number of mosaic chips in one column is 119 pcs.). The rate of mosaic panel laying – around 5.6 hours (18 445 pcs. х1,1 sec. / 60 sec. = 338 min / 60 min. = around 5.6 hours of machine operation).

The distance between mosaic chips can be adjusted, it does not affect the speed of work.

Mosaic chips feeder

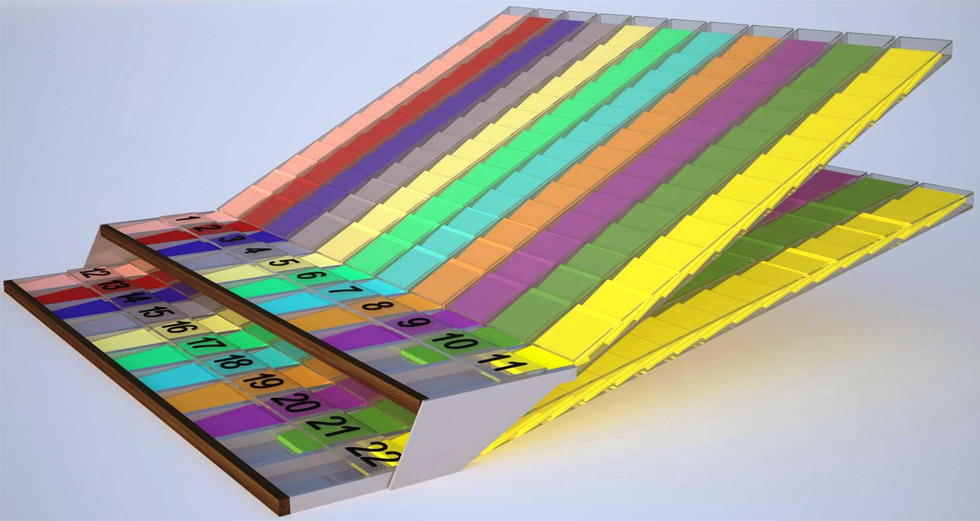

Mosaic chips feeder can have several levels.

Maximum possible number of mosaic chips simultaneous feed:

| Chip size | One-level feeder | Two-level feeder |

| 10 х 10 mm | up to 32 colors | up to 64 colors |

| 15 х 15 mm | up to 24 colors | up to 48 colors |

| 20 х 20 mm | up to 19 colors | up to 38colors |

Quality and colorfulness of mosaic pattern

Mosaic pattern colorfulness can be increased by reducing the distance between the tiles of the mosaic. By reducing the distance between the chips to 0.5 – 0.2 mm, you significantly improve the clarity and saturation of the mosaic pattern. This is achieved by:

- Reducing the empty space between the chips.

- Using more chips per unit of area.

For example, laying the chips (in the example considered – Scarlet sails) we took standard distance between the chips of 1mm with mosaic chip size of 10 х10 mm, so the distance between the chips is 10% of mosaic chip size (with mosaic chip size of 20 х 20mm the distance between the chips is10% of mosaic chip size).

If we reduce the distance between the chips by 5 times (up to 0.2 mm), we will significantly increase the clarity and saturation of the mosaic panel. In this case, the number of used mosaic chips will increase to 78,155 pieces, the time for mosaic pattern laying will increase to 37 hours (78,155 pieces * 1.7 sec / 60 sec = 2,214 minutes / 60 min = 37 hours of machine operation) .

The final color of mosaic will differ, depending on the following:

- Mosaic purpose (pool mosaic is the cheapest, it has more faded colors than mosaic for panels),

- Mosaic manufacturer (Chinese mosaic is fragile and less bright, European mosaic is brighter, but has a higher price),

- Mosaic size,

- The quality of the colors used for chips painting.

Dimensions and mosaic material

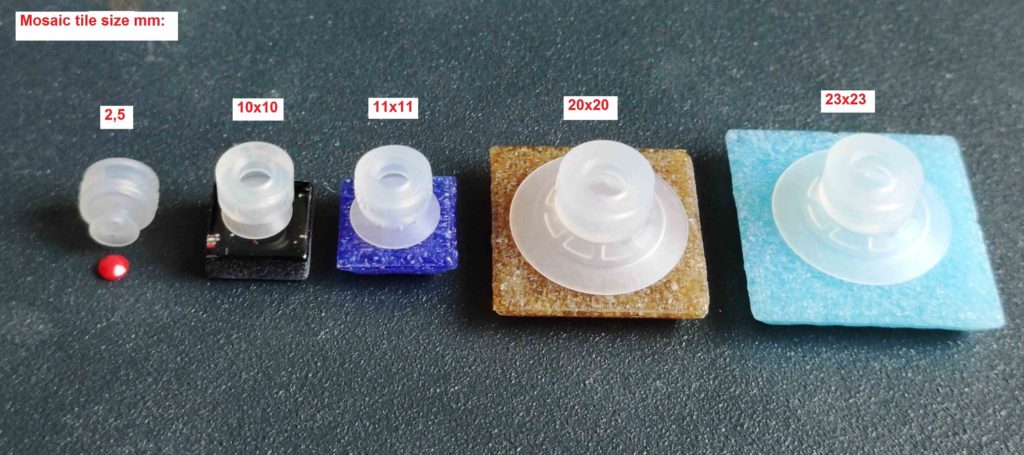

Machine operates with mosaic chip sizes of 10 Х 10mm, 15 Х 15mm, 20 Х 20 mm. At the request of the customer, the dimensions of the tiles can be changed, it is important that the sides of the chip are of the same size.

The machine works with mosaic tiles of different forms and height – even, convex, and concave. It is important that they are of the same size and smooth, for example, you can combine square, round, oval, diamond tiles with one another creating an embossed picture.

For example, the red color of the sails can be laid out with a standard smooth tile, and the pink shade of the sails can be laid out convex, creating the effect of an inflated sail.

You can combine mosaics of different materials – ceramics, stone, iron, glass, smooth clay, etc.

Accuracy of mosaic chips laying

The accuracy of mosaic chips laying is 0.01 mm. Inaccuracy arises when supplying chips from feeder, because of 0.3 – 0.7 tolerance made for mosaic chips to move freely, so mosaic chip can lie exactly in the center or deviate from it to the left or to the right.

The average deviation of chip in feeder is 0.15 – 0.35 mm for 20 х 20 mm chip. Average deviation of chip in feeder is 0.15 – 0.25 mm for 10 х 10 mm chip.

Moreover, deviation from center can be affected by chip quality. If the actual size does not meet the standard, the deviation value may be increased by the corresponding deviation.

To eliminate various deviations and make the distance between the mosaic chips equal mosaic is laid on the lattice. Lattice eliminates various deviations and makes the distance between the mosaic chips equal.

Machine can be checked and production tested. Machine is a low maintenance mechanism, reliable and easy-to-operate.

In the next five years, we plan to create robots capable of laying a chopped mosaic (with uneven faces) of the photo. The robot will be able to independently determine the colors, produce a mosaic tile, calculate the area of the broken piece, determine the size and color of the next mosaic chip, lay the chipped piece of the mosaic, etc. Robots will replace manual operations.